If you’re at all familiar with the specialty coffee industry, chances are you’ve come across many a Hario product. Hario has a broad range of items, ranging from kettles and hand grinders to pour over drippers, teapots, syphons, and servers, with many of these products featuring Hario’s famous heatproof borosilicate glass.

BORO-WHAT?

If you were to go and get a glass of water, the glass that you drink from is more than likely to be formed out of silicon dioxide, sodium oxide, and calcium oxide – or, silica, soda, and lime. If you dropped that glass on the ground, it would most likely shatter, and if you dropped it into a very hot sink of water, it might even crack from the change of temperature. Borosilicate glass does not have these characteristics, which makes it a perfect material for glass products in the coffee industry.

Borosilicate glass has an added ingredient called boric acid, which makes up 5% of the glass mixture. What this essentially does, is it creates a glass product that has an extremely high resistance to heat and severe temperature changes. It also creates glass that has an extremely high resistance to chemicals, meaning that the glass will not corrode if it comes into contact with harsh chemicals. For this reason, borosilicate glass is commonly used for cookware, LED lights, scientific lab equipment and even the storage of nuclear waste.

HOW IS IT MADE?

Hario’s heatproof borosilicate glass goes through the following process of manufacturing:

- Mixing: The ingredients are delivered into the mixer.

- Melting: The mixed ingredients are then sent to the electric melting furnace, which reaches approximately 1600°C in the middle of the furnace. (The glass itself can also act as a conductor inside the furnace!)

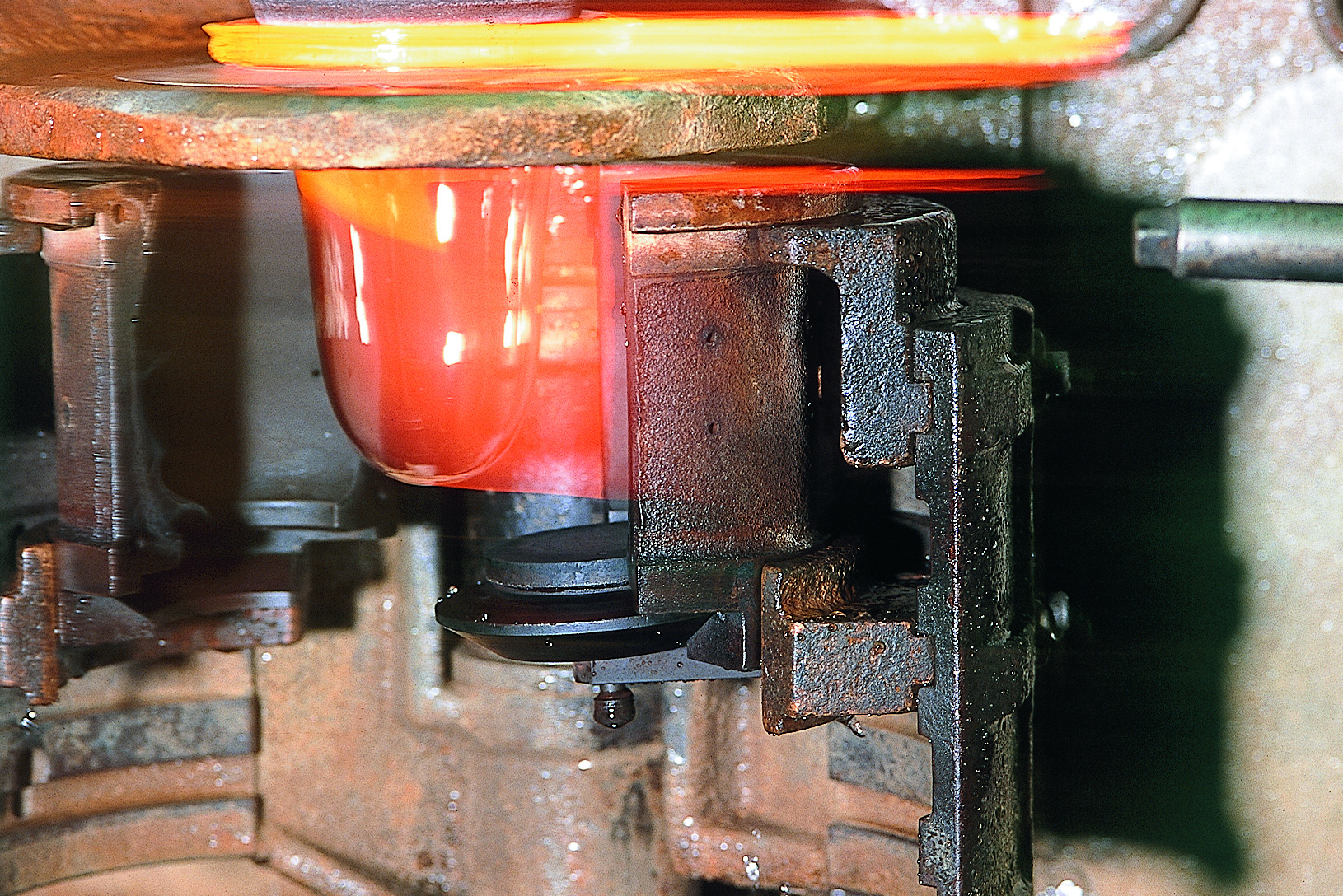

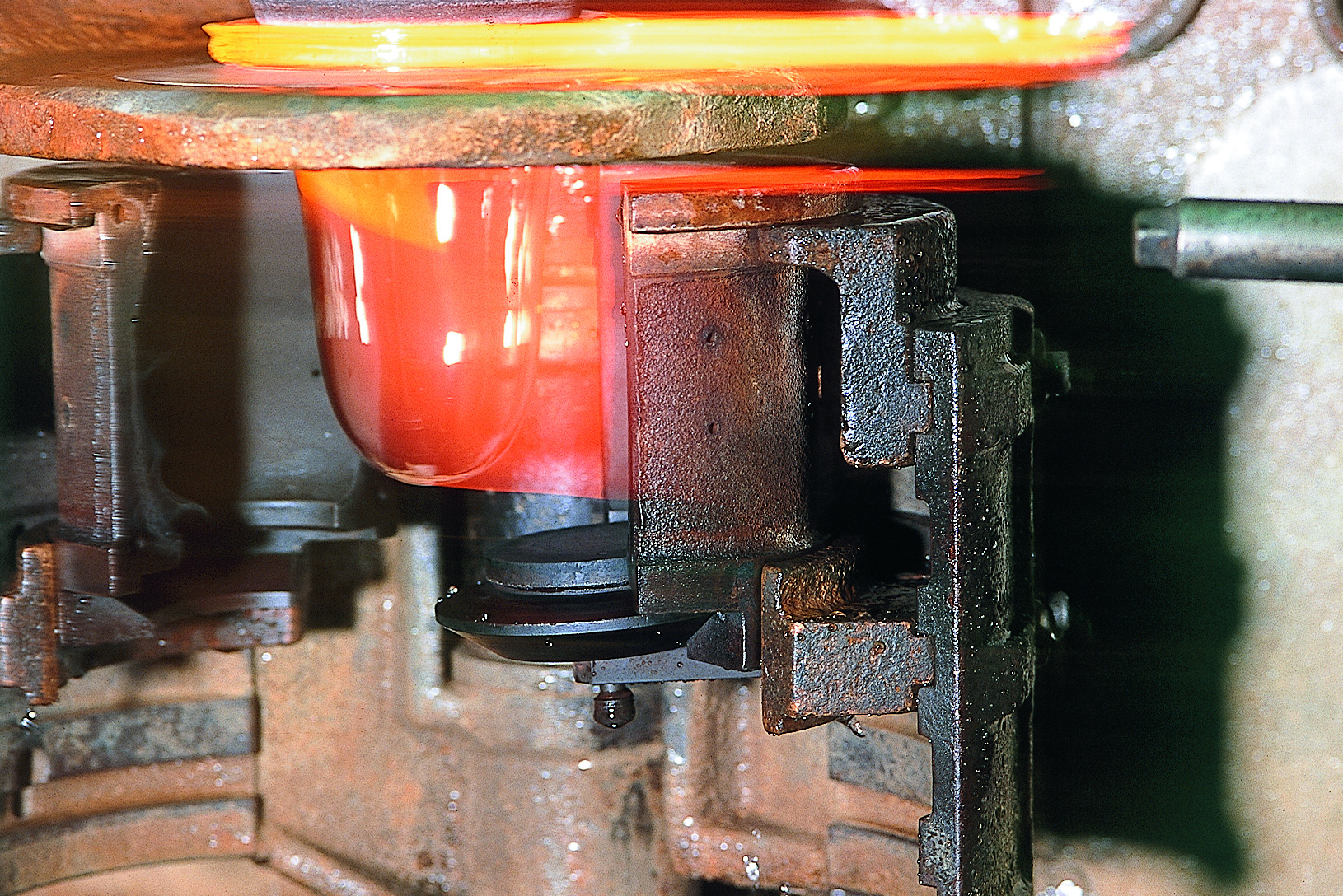

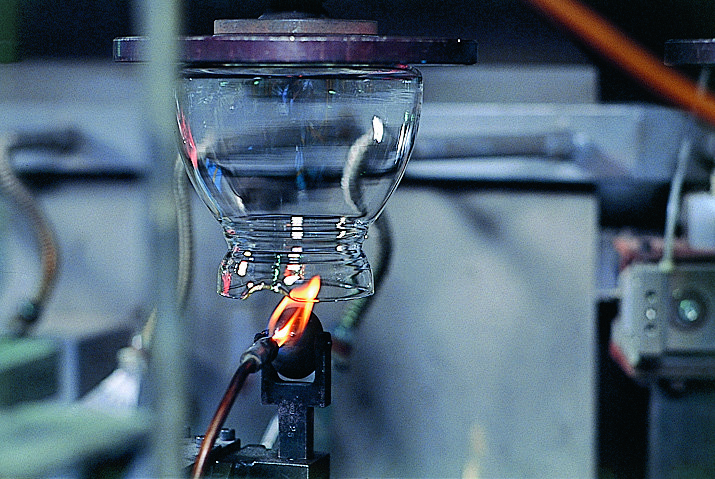

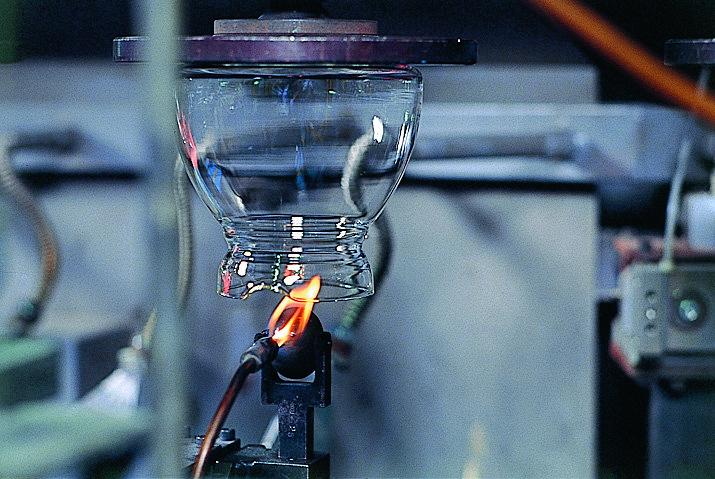

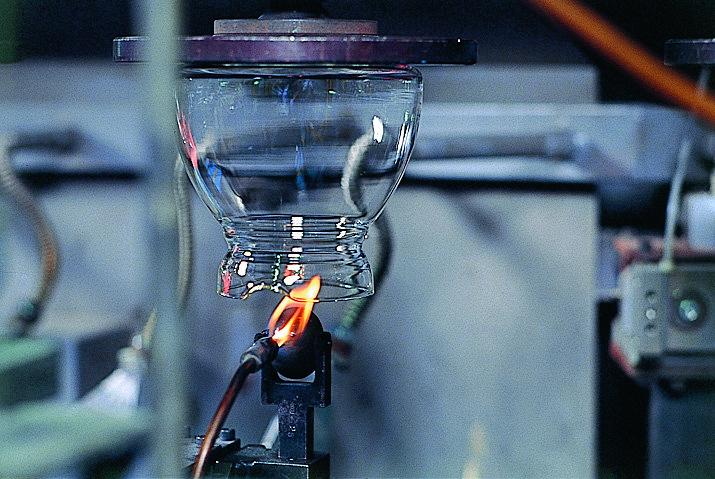

- Mould blowing: The automatic blow-moulding machine then stretches out the sphere of glass that is heated to around 1300°C. The machine spins the glass and blows pressure into the sphere to form the shape. (Fun fact: about 25 basic forms of the product can be made per minute!)

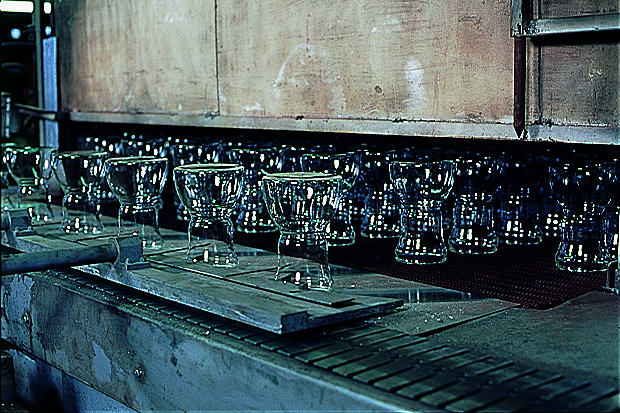

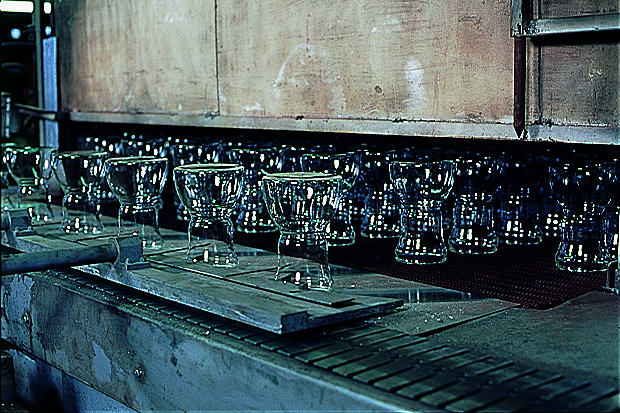

- Annealing: The products are then transferred to the lehr (a temperature-controlled kiln), where they are cooled at a slow rate depending on the thickness of the glass. The glass is cooled slowly and at controlled temperatures to avoid cracking from uneven temperatures and mechanical stress to the glass that occur from rapid cooling of molten glass products.

- Processing: The product is then processed using a computer-controlled chill cut machine, which adjusts the size and shape of the glass. Products with complex and special parts – such as the neck of a syphon or a glass handle – are processed by hand.

- Printing: Designs and marks are then printed on the products using a colour auto-printer.

- Glazing: After printing, the designs are then baked onto the products with a baking furnace, and then dried.

- Assembling: To finish, the handles, lids, and other accessories are installed, sorted into different categories and then packed into boxes.

SO WHY USE IT IN THE COFFEE INDUSTRY?

Unlike regular glass, borosilicate glass does not expand with changing temperatures, it is not affected by acid or alkali, and most importantly, it does not transfer odours or colours. This means that the flavour of coffee is not compromised. This is due to the melting process of the glass, where once the glass is melted, the surface is smooth and non-porous, with no gaps into which dirt, odour, air, and liquid can enter.

Hario glassware can be used both in the microwave and the dishwasher (unless hand-painted), due to its high melting point of 288°C, and it is more likely to snap or break into large chunks rather than shatter, making it a safer option to clean up if it does get dropped.

CHOOSING HARIO

When you choose to buy Hario products, you’re choosing to support an environmentally-friendly company. Hario makes their products from 100% raw and natural materials, and uses electricity instead of fuel for their melting process, eliminating the need for chimneys to release dust and smoke into the atmosphere.

To shop the range of Hario products at Bombora Supplies, please head here. For more information on Hario products, please feel free to use the chat module on the bottom left of your screen to chat with one of our team. Alternatively, you can give us a call on 1300 724 249.